When battery firm Johnson Matthey closed its Dundee operation five years ago it spelt the end for a skilled city workforce.

Stuart Morrison was one of 60 workers faced with the choice of relocating to Milton Keynes or being made redundant.

The company’s departure meant the end of a tradition of battery manufacturing in Dundee going back to 1941.

Stuart knew he had a choice – see Dundee lose the talented workforce or set up his own battery company.

Teaming up with a handful of Johnson Matthey colleagues, he said the decision was a “no brainer”.

He said: “We took the initiative at the time to start our own company so that we kept the know-how together and could to continue the work on battery technologies.

“Not many of us really wanted to move out of the Dundee area and who could blame us.”

MEP Technologies carrying forward tradition of battery manufacture

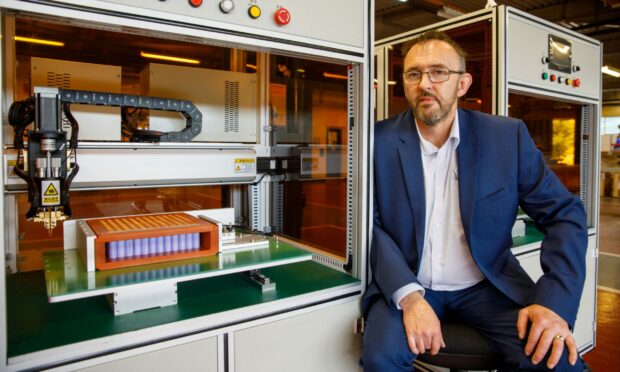

The move resulted in the birth of MEP Technologies with Stuart in the role of managing director.

He is proud to “pick up the torch” of battery manufacturing in Dundee.

Stuart said: “Ever since 1941, there’s always been a company in Dundee who manufactures batteries.

“That’s another thing we’re proud of. When Johnson Matthey decided to move out, we picked up the torch locally and carried on.”

The firm has expanded in the last five years and the 14-person team was the first to move into Michelin Scotland Innovation Parc in November.

Currently occupying a 4,500 sq ft site, MEP will move to a production site double that size in the new year.

The move will give the firm space to work on their upcoming projects, the electrification of a tractor and creating a fire-safe battery enclosure.

Plans for more jobs soon

MEP is capable of building around 15,000 suitcase-sized battery packs a year.

With plans to buy more equipment and take on more people, Stuart estimates this could grow to 50,000 battery packs annually within eight months.

He said: “We’ve got ambitions. We are likely to take on somewhere between five and 10 more people within the next year, so we are growing fairly quickly.”

By building more batteries, MEP become an important part of the shift away from fossil fuels and towards sustainable methods of transport.

MEP’s work with electric vehicles

The firm are also part of a project to make electrical vehicles safer.

It is collaborating on a project to create a battery pack which can detect and suppress fire.

For Stuart, finding new sustainable solutions is simply part of the job.

He says: “When you treat this day to day, you forget that you are part of the bigger picture and that there’s a lot of other aspects of society riding on you.

“I guess I’m proud that were part of the industry that supports that whole shift.

“As a company we’re just doing our bit.”