A Dundee university graduate has lofty plans for a business he created when his own body prevented him from joining the cycling boom last summer.

Glen Craig was unable to follow in the path of thousands across the UK and start cycling during lockdown last year.

At the start of the pandemic, statistics released by Cycling Scotland showed there was a 215% increase in folk getting on their bikes in Dunfermline alone.

There was also a 94% surge in cycling in Dundee.

What was it that kept Glen off his bike? Nothing, except his height.

The 6ft 7in Duncan of Jordanstone College of Art & Design graduate found that bikes in non-standard sizes were extremely hard to come by.

He said: “I really struggled to find a bike last summer.

“One, because of the shortage in stock and two, they don’t really have bike frames big enough for people of my height.

“My only options were custom-made, hand-built bikes, which can be really expensive.”

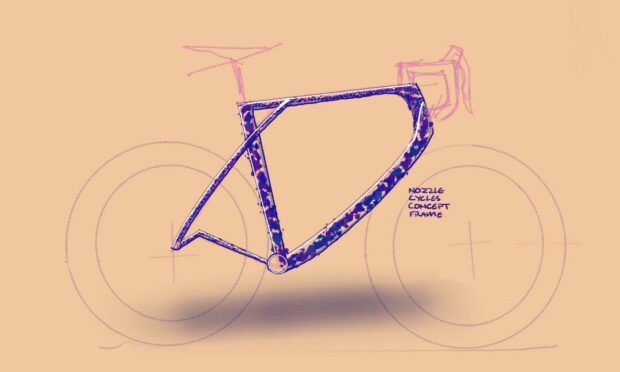

Nozzle Cycles: Helping others with custom bikes

So the 22-year-old took matters into his own hands.

The gap in the market inspired him to investigate the capabilities of 3D printing to help other cyclists of all shapes and sizes.

Glen, who studied product design, began putting plans together in the final year of his course.

His dissertation was the first version of his business plan for Nozzle Cycles.

Glen said: “I put two and two together and realised there was a gap in the market.”

“It was initially focused on taller people, like myself.

“But I soon realised that it’s not just tall people who have difficulties finding the right bike size.

“People of all shapes and sizes, and people who are disproportionate, who might have longer legs or shorter arms for example, also struggle.

“Nozzle aims to provide the perfect fit and customisations for all riders, creating comfortable and safe rides.

“By providing a tailored fit, chances of injuries or strain will be reduced and it will create a better riding experience.”

Plans to make custom bikes affordable

Glen hopes to make custom bikes at an affordable cost, while also slashing waiting times.

He has been named as a Converge 2021 finalist in the KickStart category.

The top prize for the KickStart challenge is £10,000, with a runner-up prize of £5,000.

He said: “There’s already a market for custom made bike frames, but the majority are hand-built and extremely expensive.

“Prices can go upwards of £10,000 and waiting times are long.

“By using 3D printing we can cut the cost, speed up the process and minimise any waste being produced.

“I’m hoping one frame would be made within a few days of starting the printing process.

“After this, post processing, including painting and assembly of components, would only take another 2-4 days.

“It’s an amazing group of technologies.

“They are constantly developing and becoming more cost effective, meaning a promising future for Nozzle.”