The sky is literally the limit when it comes to the latest in farm technology.

The use of unmanned aerial vehicles (UAVs) – or drones as they are popularly known – is now becoming relatively common, but Brechin-based precision farming specialists SoilEssentials is taking the whole concept of data collection and use to a new level.

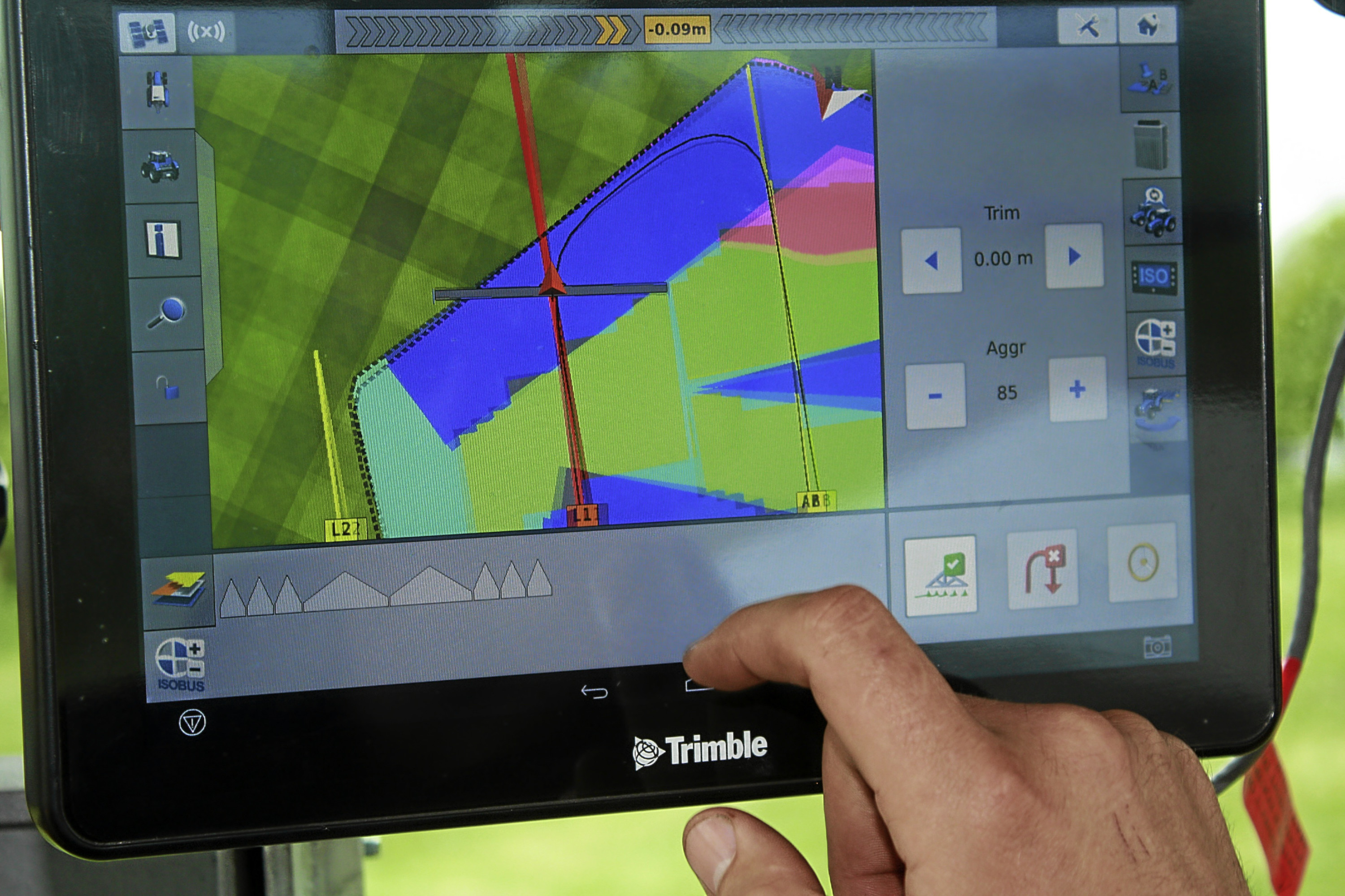

At a field day at Finavon, SoilEssentials director Jim Wilson explained how the company had worked with international technology supplier Trimble to develop a system to be known as Connected Farm.

“As an example of how quickly data can be processed and used we can send a drone on a pre-planned route across a field to assess crop condition and requirements.

“As soon as the data is received it can be uploaded to a SoilEssentials website using the grower’s own private log-in details.

“Within an hour it will be possible to create a variable-rate application map for fertiliser or pesticides which can then be sent on to the terminal in the tractor,” he said.

“Because it is web-based, the tractor could in theory be operating anywhere in the world.

“The days of keeping data on a memory stick in your trouser pocket which then goes through the washing machine are over.”

Severine Brisset, sales manager for Trimble France, said her company was keen to see its technology developed by regional companies – and this is exactly what SoilEssentials had pioneered by developing the first such system in Europe.

A further benefit is that the grower or contractor can use the system to see exactly where each tractor is at any time.

Mr Wilson said: “Also, multiple tractors in the same field can share data.

“This is useful at potato-planting time. The tractor on the deep-ridger can take a line using GPS auto steering which will then be shared with the stone separator and the planter.

“Previously each machine was taking its own start line, which could be slightly different from the deep-ridger.”

SoilEssentials also used the Finavon event to demonstrate the next level of RTK autosteering.

RTK signals allow for precision steering to an accuracy of 25mm (one inch) up the field, but it can sometimes be difficult to place the tractor in the right place for the next pass.

The latest development guides the tractor hands-free on headland turns.

Graham Ralston, who is manager for machine control with the company, said: “There are big savings to be made by making turns as efficiently as possible.

“This gives complete accuracy even when the tractor is set to miss swathes to give a longer turn-in. It can be set to miss, say, two swathes, with the system automatically filling in the missing swathes as the machine works across the field.

“With a grain drill it can be programmed to still place the tramlines in the correct pass.”

There are three machines in Scotland already working with this additional auto-steer feature – two on grain drills, and one on a fertiliser spreader.

A Massey Ferguson tractor with a Kuhn fertiliser spinner was on display yesterday featuring Trimble Autopilot and variable-rate application, including incremental automatic cut-off for use in fields with gussets or tapered headlands.