With just days until the opening of the Queensferry Crossing over the Forth, Michael Alexander meets some of those tasked with building the biggest transport project in a generation.

It’s been almost 10 years in the planning, six years in the building and has taken 15,000 workers the equivalent of 20 million man hours to construct.

But when vehicles are allowed to cross the £1.35 billion Queensferry Crossing for the first time in the early hours of Wednesday morning (AUG 30), it will be a relatively low key operation that swings into action after weeks of last minute behind the scenes activity.

At some point during the night when traffic is “at its quietest” barriers will be removed and history will be made as all vehicles are diverted from using the old Forth Road Bridge on to the new crossing.

Transport Scotland says it won’t be pinned down to an exact time for the unofficial opening. It’s understood this is because they don’t want to attract “wacky racers” competing to be the first to cross.

But importantly, the days that follow will be an invaluable opportunity for the bridge operators to “dry run” any traffic management issues before the bridge closes again to allow 50,000 lucky ticket holders the once in a lifetime chance to walk over the new bridge on September 2 and 3.

The Queen will officially open the crossing on September 4 – which also happens to be the 53rd anniversary of the day she opened the original Forth Road Bridge.

Then on September 5, an additional 10,000 people from local schools and community groups from both sides of the Forth will have the chance to walk onto the new bridge before it re-opens to motorway traffic the day after with no pedestrian access.

Transport Scotland says public transport will be diverted back on to the old Forth Road Bridge around four or five weeks later.

It’s been an exciting few years for residents and drivers who have seen the new bridge take shape, from the arrival of the huge container ships carrying the bridge’s 1,200 tonne steel caissons – or foundation moulds – in May 2012, to the rising of the three towers from the Forth, stretching of the bridge cables and the eventual connection of the 35,000 tonne bridge deck.

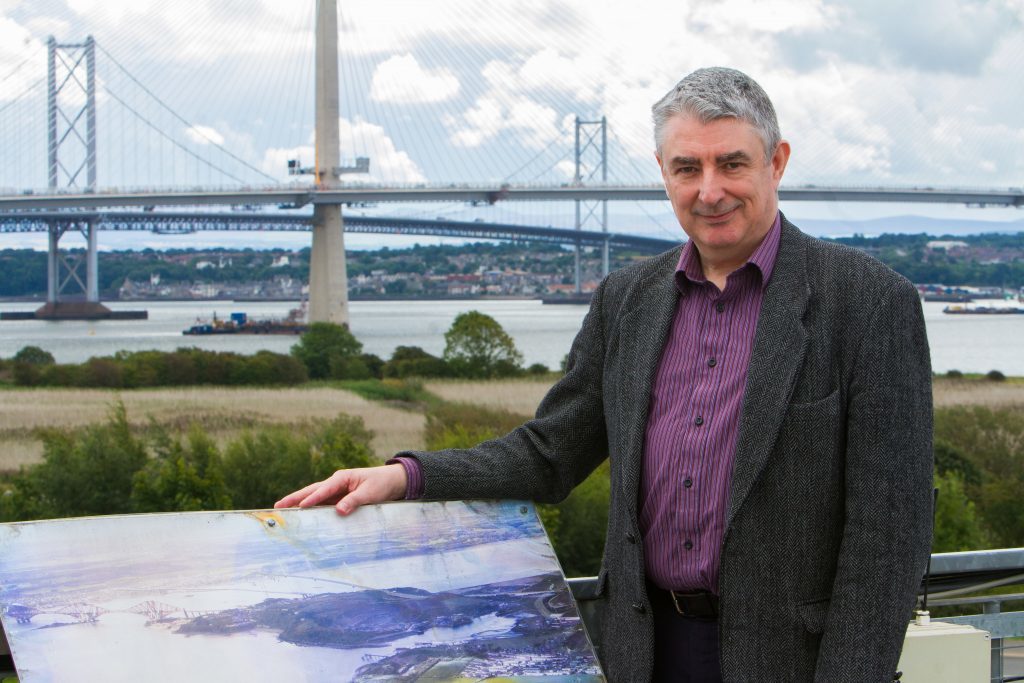

For Queensferry Crossing project director and “local lad” David Climie, however, there’s been the added satisfaction of knowing that he has overseen the biggest transport project in Scotland for a generation.

The London-born and Perth-raised 56 year-old, who studied civil engineering at Heriot Watt University in Edinburgh, has many pins in a fascinating career map that so far includes Egypt, Hong Kong, China, Denmark, the United States and of course the Firth of Forth where he previously worked on strengthening of the old bridge’s cross-bracings in the late 1980s.

But he admits that to have been Transport Scotland’s project director for the Forth Replacement Crossing, as it is technically known, has been “pretty remarkable”, with everyone involved incredibly proud of the “monument” they are about to leave behind.

“I started just over seven years ago – I came into the job in the middle of 2010,” he explains in an exclusive interview at the Forth Crossing Bridge Constructors project office within sight of the bridge at Rosyth.

“At that point the bill was going through the Scottish Parliament, the procurement was just under way and we were in the competitive dialogues for the various contracts.

“At that point we knew what we wanted to do – we knew we had a very ambitious timetable to achieve it.

“But to go from a blank piece of paper to a finished piece of infrastructure like this in 10 years is pretty remarkable.”

David’s office is housed in a compound close to Rosyth Dockyard within a semi-permanent multi-storey office block that was transported north after being used for the pre-planning of the 2012 Olympics in London.

As Scottish Government client representative, David’s job has been less hands-on than he’s been used to in previous employment.

But he’s still managed to visit the bridge at different phases of construction and has been able to keep an eye on its progress with an unrivalled view from his office window.

At the time of The Courier’s visit, the final road surface is down, the white lines have been painted and site cabins have been removed from the decking. “It now looks like a finished bridge!” declares David.

Such is the vastness of the project, however, finishing touches to the approach roads, decking and towers will go right to the wire ahead of opening.

It was December 2007 when Finance Secretary John Swinney first announced that a new cable stayed-style bridge would be built across the Forth amid concerns over the viability of the existing suspension crossing and its corroding cables.

Ruling out a tunnel, he announced the new bridge would open in “about 2016” – a timetable that slipped slightly due to bad weather – and would cost between £3.2bn and £4.2bn – a tab that’s been significantly reduced to £1.35bn for various reasons including the realisation that the existing bridge can be retained for public transport – an option which was initially in doubt.

The death of a construction worker in an incident on the bridge in April last year inevitably impacted on the team.

“Regrettably, the single fatality that we had had nothing to do with the main construction work on the bridge,” David reflects. “It was a bit of maintenance on a bit of plant on the bridge. It really did affect the whole project and the one thing that we really wanted to avoid.”

But the team bounced back and from an engineering perspective, the 1.7 mile (2.7km) bridge, honouring the Forth’s 11th century links with Queen Margaret, boasts a number of special features.

Apart from being the longest three tower cable stayed bridge in the world, the centre tower was officially recognised by the Guinness Book of World Records last October as being the longest, free-standing, balanced cantilever ever built.

The bridge, with a 120-year design life, has also been built with 3.6m high wind shielding – which theoretically means she may never have to close to high sided vehicles – while the two primary traffic lanes in each direction are supplemented by wide hard shoulders to reduce congestion in the event of a break down.

With 24 million vehicles per year using the Forth Road Bridge compared with just four million when she opened in 1964, the Queensferry Crossing has been future proofed with the hard shoulders able to absorb traffic loading in future if required.

Crucially, there’s a dehumidification system inside the box girder to prevent corrosion while the cable stayed design also means that individual pre-sealed cable strands can be replaced with the bridge still in operation.

With regular inspections the key to its longevity, structural health monitoring systems have been incorporated into its design including strain gauges in the cables and sensors in the deck all reporting back to the bridge control room.

Michael Martin is project director for Forth Crossing Bridge Constructors (FCBC) – the main contractor responsible for the design and construction of the Queensferry Crossing comprising a consortium of Hochtief from Essen, Germany; Dragados from Cadiz, Spain; American Bridge from Pittsburgh, USA and Morrison Construction, originally from Inverness.

He says: “For civil engineers, the chance to build a bridge of the sheer scale and engineering significance of the Queensferry Crossing is a dream come true.

“For most of us, it will surely be a once-in-a-lifetime project that, no matter what other challenges we go on to tackle in our careers, will definitely be hard to match.

“I know from speaking to the FCBC team who have designed and built this wonderful new bridge and its vital connecting roads that we are all immensely proud of what has been achieved in such a short timescale.

“That pride is only increased when we see ‘our’ completed bridge sitting alongside its neighbours, two of the most famous bridges in the world.

“Building something like this, out in the middle of an estuary in often very hostile weather conditions, you know major challenges will be thrown at you on an almost daily basis.

“Some might say, “Well, that’s civil engineering for you”. True, but I am especially proud of the way the members of the team have faced up to the challenges on this project and overcome every one of them in such a skilled and professional manner.

“The Queensferry Crossing represents civil engineering at its very finest.”

https://www.youtube.com/watch?v=xD9wWeo7jqA