A milestone has been reached on the new Queensferry Crossing as the road links to the north shore for the first time.

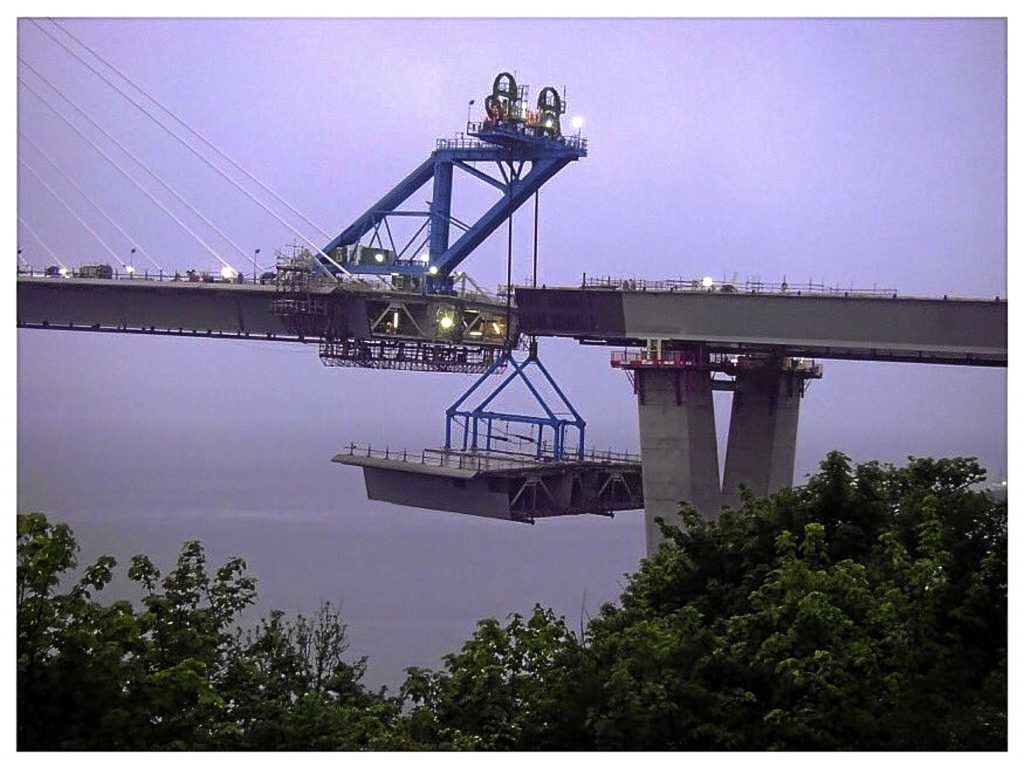

The final segment of deck was put in place which means that the bridge’s north tower is joined with the north approach viaduct into Fife.

However, highly complex work is now starting to ensure a smooth ride for drivers who will use the new £1.3 billion crossing when it opens.

A Transport Scotland spokesman explained the two sections of deck are not yet level.

They said: “At present the deck fan from the north tower is lower than the viaduct deck, with a 300mm gap between the two.”

This 300mm gap will be levelled by counterbalancing the tower deck with a further deck section at the south end of the fan and then attaching and tensioning the stay cables to the deck unit.

There is then a complex technical process of fine tuning the various temporary loads the superstructure faces during construction before the 300mm gap will be fully closed later in the year.

It comes only two months after the north viaduct was fully launched as engineers completed the complex task of pushing the structure of the viaduct out across the new bridge’s distinctive v-shaped piers on the north side of the Forth.

It was called one of the most technically challenging operations of its kind ever performed by Michael Martin, the project director for the Forth Crossing Bridge Constructors consortium.

A massive total of 6,300 tonnes of steel and concrete were pushed out 230 metres, which in itself was a significant feat of engineering.

But what made it even more tricky was that the consortium building the bridge had to slide the edge of the moving structure down two ramps to raise its front edge by two metres.

This allowed them to pivot it over the top of one of the two support piers as it moved forward above the firth, so that the viaduct was at the correct position to match the emerging deck fanning out from the north tower.

Mr Martin said some of the best engineers in the world had used ingenuity to design and build the structure and devise the method of safely launching it into position.

“This is the kind of work being delivered on a daily basis right across this amazing project,” he added.

It is due to open in December.