Levi’s decided to axe its Dundee factory 20 years ago in what was a bad dose of the winter blues for its 462-strong workforce.

The workforce was told to go home at lunch-time and to stay away until further notice following the devastating announcement in January 2002.

The company’s Bellshill factory was also included in the closure proposal with a combined loss between the two plants of 647 jobs.

The San Francisco-based company was attempting to restore its faded image in the face of competition from other brands that had cut into its once-dominant market share.

Levi Strauss began its 30-year association with Dundee in 1972 and nearly 600 people worked at its plant in Broomhill Road at its height in the 1990s.

The announcement followed persistent speculation over Christmas that one or both of the plants – in Dundee and at Bellshill – could be at risk.

Alan Christie, of Levi’s Europe, said the closure proposal was taken after the company had “done its sums”.

Those sums led Levi’s to claim that production costs at its Dundee sewing factory were up to 60% higher than elsewhere in Europe.

Products made in Dundee were finished at the Bellshill factory, where costs were said to be 40% higher than those at other European plants.

In a nutshell, that was why Levi’s wanted to pull the plug.

Comparison with a European average suggested that the building in Dunsinane Industrial Estate was not necessarily the most expensive to operate.

Be that as it may, the company said its sales were down 8.3%, income had declined and it was having to fight to hang on to what it could of its global market share.

The announcement coincided with news of the company’s year-end financial results, which included the possible closure of a number of US factories.

Frank Ross, sourcing director denim for Europe, the Middle East and Africa, said: “We must reduce our average European production costs.

“The cost of producing jeans at our Dundee sewing plant is almost 60% more than the average of our other plants across Europe.

“We very much regret the necessity of proposing this action.

“Should our proposal be accepted, we will do whatever possible to help all affected employees.

“I would like to emphasise that these proposed measures in no way reflect on the quality work and high standards of our employees at Dundee and Bellshill who, for many years, have consistently shown their commitment to the company and to its products.”

Dundee’s higher production costs were said to be the result of higher wages.

The company said it had not made a final decision to close the plants but, crucially, it said it had investigated all other options and “can see little alternative”.

Production at both factories had been effectively suspended since the announcement in January, with workers still being paid, but to stay at home.

Faint hope that the Levi’s plant in Dundee could be spared closure evaporated following a report produced by Professor Robert van der Meer of Strathclyde University.

The management guru was brought in by unions and bosses in February 2002 in an attempt to find an alternative to closure.

He studied the production facilities at the Broomhill Road plant, had talks with local management and examined various financial details and other information.

Professor van der Meer confirmed Levi’s own findings that there was no alternative to the closures of the Dundee and Bellshill factories.

Ian King from the GMB union then asked the workforce to “accept the inevitable”.

Employees in Dundee and Bellshill overwhelmingly agreed to accept the redundancy package, which was described as “second to none”.

“The agreement is the same for workers at both plants,” said Mr King.

“It’s now a done deal and we have been able to negotiate a significant package for our members.”

At Dundee, where the average length of service was just over 12 years, workers received the equivalent of more than one year’s wages, while long-serving employees who had been with the company for almost 30 years were given more than two years’ wages.

Included in the deal was the agreement of a bonus payment for workers to return to work to assist in the winding-up process and complete all orders in progress.

The plant closed on March 28 2002.

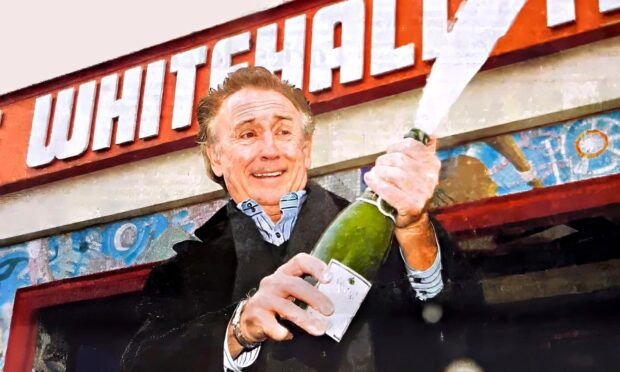

Levi’s staff marked the closure of the Dundee plant by popping the cork on some champagne.

More like this:

Trip back in time: The Levi’s factory in Dundee that made a million pairs of jeans every week

G.L. Wilson: Step inside Dundee’s beloved ‘friendly store’ once more thanks to archive images